Soap. It’s something most of us use daily, often without a second thought. We lather up, rinse, and repeat, confident in its cleansing power. But beneath that simple act lies a surprisingly consistent science, stretching back millennia. From ancient recipes painstakingly developed through observation to modern chemical engineering, the core principles of soapmaking have remained remarkably stable. This article will explore that journey, diving into the history, chemistry, and artistry of this essential substance.

A History Steeped in Alkali and Fat

The earliest evidence of soap-like substances dates back to ancient Babylon around 2800 BC. These weren’t quite the soaps we know today; rather, they were mixtures of fats boiled with wood ashes. The ashes provided the crucial ingredient: alkali. Ancient Egyptians used a similar combination of animal fats and alkaline salts around 1500 BC. The Ebers Papyrus, an ancient Egyptian medical text, contains a recipe for a soap-like substance intended for use in treating skin diseases and preparing mummies. These early soaps weren’t primarily for cleaning, as we think of it today. They were more likely used for medicinal purposes, textile processing, and even as early forms of cosmetics.

The Phoenicians, renowned traders, are credited with spreading the knowledge of soapmaking throughout the Mediterranean. The Greeks, however, initially preferred olive oil for cleansing and bathing, viewing soap as a barbaric practice. It wasn’t until the Roman Empire that soap gained wider acceptance, becoming a staple in public baths and gaining recognition for its cleaning properties. Pliny the Elder, a Roman author and naturalist, documented several soap recipes in his Natural History.

Throughout the Middle Ages, soapmaking remained a localized craft, often practiced by women. Recipes varied widely depending on the available fats and alkalis. Olive oil was prevalent in Mediterranean regions, while animal fats were more common in Northern Europe. The quality of soap depended heavily on the purity of the alkali source, which was often obtained by leaching wood ashes with water. This process yielded a potassium-rich solution, which was used to saponify animal fats.

The Chemistry of Saponification: A Timeless Reaction

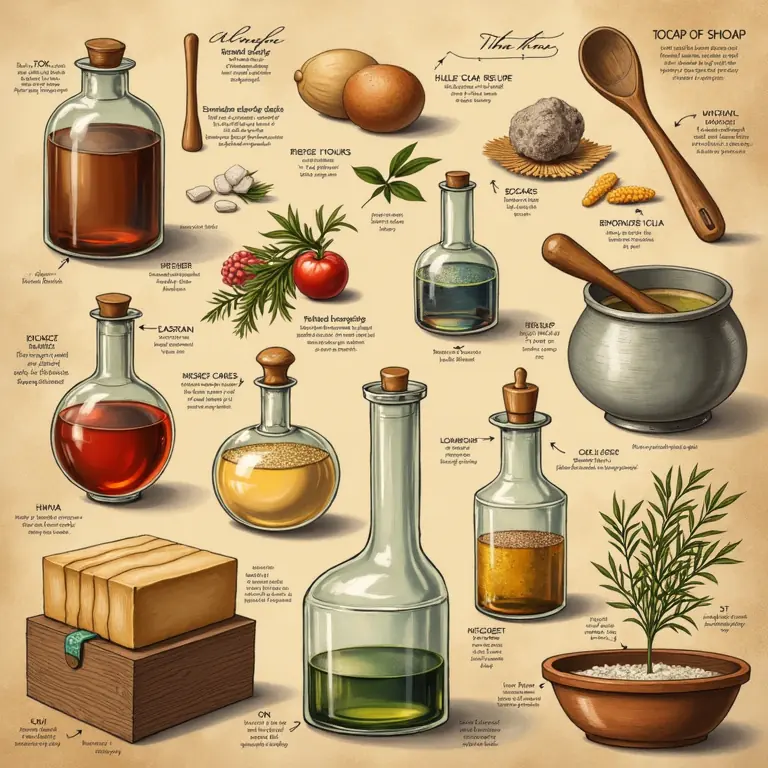

The heart of soapmaking lies in a chemical reaction called saponification. This is the process of combining fats or oils with an alkali to produce soap and glycerin. The word “saponification” itself comes from the Latin word “sapo,” meaning soap. Let’s break down the chemistry:

Fats and oils are composed of triglycerides. A triglyceride is a molecule formed from a glycerol backbone attached to three fatty acid molecules. Fatty acids are long chains of carbon and hydrogen atoms with a carboxyl group (-COOH) at one end. Alkalis, like sodium hydroxide (NaOH) or potassium hydroxide (KOH), are bases that contain hydroxide ions (OH-).

When an alkali is mixed with a fat or oil, the hydroxide ions attack the ester bonds linking the fatty acids to the glycerol backbone. This breaks the triglyceride into its constituent parts: fatty acid salts (soap) and glycerol. The fatty acid salts are what give soap its cleansing properties.

Here’s a simplified representation:

Triglyceride + Alkali → Soap + Glycerol

The type of alkali used determines the type of soap produced. Sodium hydroxide creates a hard soap, commonly used for bars. Potassium hydroxide creates a softer, more liquid soap, often found in liquid hand soaps.

The Role of Fats and Oils: Variety is the Spice of Soap

The characteristics of the fats and oils used significantly impact the final soap’s properties. Different fatty acids contribute different qualities to the soap. For example:

- Lauric acid (found in coconut oil and palm kernel oil) produces a hard, bubbly soap with excellent cleansing power.

- Myristic acid (found in coconut oil and palm kernel oil) contributes to hardness and lather.

- Palmitic acid (found in palm oil and tallow) creates a hard, stable soap.

- Stearic acid (found in tallow and vegetable shortening) adds hardness and opacity.

- Oleic acid (found in olive oil and sunflower oil) produces a mild, moisturizing soap.

- Linoleic acid (found in sunflower oil and safflower oil) contributes to a softer, more conditioning soap.

Soapmakers carefully blend different fats and oils to achieve desired characteristics, such as hardness, lather, moisturizing properties, and cleansing power. A soap made entirely from coconut oil will be very cleansing but potentially drying. A soap made primarily from olive oil will be mild and moisturizing but may not lather as abundantly. The art of soapmaking, therefore, lies in finding the perfect balance.

From Lye to Luxury: The Evolution of Alkali Sources

As mentioned earlier, early soapmakers relied on wood ashes as their source of alkali. This method, while effective, was inconsistent and produced a soap containing impurities. The quality of the ash depended on the type of wood burned and the leaching process.

A significant breakthrough came with the development of methods for producing pure sodium carbonate (soda ash) from salt. Nicolas Leblanc, a French chemist, patented a process in 1791 for converting common salt (sodium chloride) into soda ash. This process revolutionized soapmaking, providing a reliable and consistent source of alkali.

Later, the Solvay process, developed in the 1860s, offered a more efficient and environmentally friendly method for producing soda ash. This process involved reacting ammonia, brine (salt water), and carbon dioxide.

Today, commercially produced soap relies almost exclusively on industrially produced sodium hydroxide and potassium hydroxide. These alkalis are manufactured through the electrolysis of brine. This process separates the salt into its constituent elements, yielding chlorine gas, hydrogen gas, and sodium hydroxide.

The Art and Science of Cold Process Soapmaking

While industrial soapmaking involves large-scale processes and automated equipment, many individuals still practice artisanal soapmaking. One popular method is cold process soapmaking. This technique involves carefully mixing fats and oils with a lye solution (sodium hydroxide dissolved in water). The mixture is stirred until it reaches “trace,” a point where it thickens enough to leave a visible trail when drizzled across the surface. At this point, fragrances, colorants, and other additives can be incorporated. The soap is then poured into a mold and allowed to saponify over several weeks. During this time, the saponification process continues, and the soap hardens and matures.

Cold process soapmaking requires precision and caution. Lye is a corrosive substance and must be handled with appropriate safety precautions, including wearing gloves and eye protection. However, once saponification is complete, there is no residual lye in the finished soap.

Here’s a helpful video demonstrating the cold process:

Beyond Cleaning: Additives and Their Functions

Modern soaps often contain a variety of additives designed to enhance their properties. These include:

- Fragrances: Essential oils or synthetic fragrance oils add scent.

- Colorants: Natural clays, plant extracts, or synthetic dyes provide color.

- Moisturizers: Glycerin, shea butter, cocoa butter, and other oils add moisturizing properties.

- Exfoliants: Oatmeal, poppy seeds, or ground nuts provide gentle exfoliation.

- Herbs and Botanicals: Dried herbs, flowers, and other plant materials add visual appeal and potential therapeutic benefits.

- Chelating agents: Ingredients like tetrasodium EDTA help to bind metal ions, preventing them from interfering with the soap’s lathering ability, particularly in hard water.

The inclusion of these additives allows soapmakers to create a wide range of products tailored to specific needs and preferences.

The Future of Soap: Sustainability and Innovation

The soap industry, like many others, is facing increasing pressure to adopt sustainable practices. This includes sourcing fats and oils responsibly, minimizing waste, and reducing the environmental impact of production. There’s a growing trend towards using plant-based oils and avoiding palm oil, which is associated with deforestation.

Innovation in soapmaking continues. Researchers are exploring new surfactants (surface-active agents) that offer improved cleansing and foaming properties. There’s also interest in developing soaps with antimicrobial properties or those that can deliver active ingredients to the skin.

The consistent science behind soapmaking provides a solid foundation for these innovations. By understanding the fundamental principles of saponification and the properties of different ingredients, soapmakers can continue to create effective, sustainable, and enjoyable cleansing products.

Consistency Across Disciplines

Interestingly, the underlying principles of consistent observation and experimentation in soapmaking echo those found in other seemingly disparate fields. The meticulous documentation of recipes and results mirrors the scientific method employed in areas like dream interpretation – see the surprisingly consistent science of dream interpretation across cultures. Similarly, the harmonic relationships between ingredients and their effects on the final product find resonance in the study of clock chimes, as explored in the surprisingly consistent science of clock chimes history, harmony and horology. Even the naming of ingredients, tracing their origins and evolving meanings, parallels the etymological consistency discussed in the surprisingly consistent etymology of food names from origins to our plates. The intricate craftsmanship involved in artisanal soapmaking also shares a common thread with the delicate art of Victorian hairwork, detailed in the surprisingly consistent art of Victorian hairwork mourning, memory and intricate craftsmanship, and even the precise tension and structure required in creating strong knots, as examined in the surprisingly consistent science of knot strength from ancient rigging to modern materials. These examples demonstrate a pervasive human tendency to seek order and consistency in understanding the world around us.

The Curious Acoustics of Historical Echo Chambers: Resonance, Ritual, and Revelation

The Curious Acoustics of Historical Echo Chambers: Resonance, Ritual, and Revelation  The Curious Chemistry of Lost Colors: Pigments, History, and the Art of Remembrance

The Curious Chemistry of Lost Colors: Pigments, History, and the Art of Remembrance  The Curious Cartography of Scent: Mapping Perfume Ingredients Through History

The Curious Cartography of Scent: Mapping Perfume Ingredients Through History  The Curious Lexicon of Lost Trades

The Curious Lexicon of Lost Trades  The Surprisingly Consistent Science of Historical Ice Harvesting – A Frozen History of Commerce & Preservation

The Surprisingly Consistent Science of Historical Ice Harvesting – A Frozen History of Commerce & Preservation  The Unexpectedly Consistent Science of Historical Buttonhooks – Fashion, Function & Forgotten Tools

The Unexpectedly Consistent Science of Historical Buttonhooks – Fashion, Function & Forgotten Tools