For many, a vintage sewing machine evokes images of grandmother’s attic, carefully crafted quilts, and a slower, more deliberate pace of life. But beyond the nostalgic charm lies a fascinating world of engineering, precision mechanics, and surprisingly consistent scientific principles. These machines, spanning the late 19th and 20th centuries, weren’t simply tools; they were testaments to innovation, evolving from hand-cranked novelties to electrically powered engines of home fashion. This article delves into the core mechanisms that drove these machines, the incremental yet significant innovations that shaped their development, and the cultural impact they had on the democratization of dressmaking.

The Dawn of Mechanized Sewing: From Hand to Machine

Before the advent of the sewing machine, clothing construction was a laborious, time-consuming process, largely confined to skilled seamstresses and the wealthy. While rudimentary sewing devices existed for centuries – the needle, the thimble, and various forms of stitch-forming tools – the idea of a mechanized solution didn’t truly take hold until the 19th century. Early attempts, like those by Thomas Saint in 1790 (patented, but never commercially produced), focused on automating the stitching process. However, it was Elias Howe Jr.’s 1846 invention, with its lockstitch mechanism, that truly revolutionized sewing. His machine, though initially met with resistance, laid the foundation for the industry.

However, Howe’s machine wasn’t the final word. Isaac Singer, recognizing the need for a more practical and commercially viable design, refined Howe’s invention, introducing features like the treadle drive and a more efficient needle system. Singer’s marketing prowess and focus on ease of use propelled the sewing machine into the homes of millions. The early machines, though groundbreaking, were still relatively simple in construction, relying heavily on the interplay of gears, levers, and carefully calibrated mechanisms.

The Core Mechanics: A Symphony of Gears

At the heart of every vintage sewing machine lies a complex, yet elegant, system of gears. These aren’t just randomly arranged cogs; they are meticulously designed components working in harmony to transform rotary motion into the precise, reciprocating movements needed to form a stitch. Let’s break down the key elements:

- The Flywheel: Often the most visually prominent part, the flywheel serves multiple purposes. It stores rotational energy, smoothing out the power delivery from the hand crank or motor. A larger flywheel provides greater inertia, making the machine easier to start and maintain a consistent speed.

- The Main Shaft: Connected to the flywheel, the main shaft transmits power to the other components of the machine. Its diameter and construction influence the overall speed and torque of the machine.

- The Cam System: This is where the magic happens. Cams, shaped metal discs with eccentric profiles, translate rotary motion into linear motion. Different cam profiles control the movement of the needle bar (up and down) and the feed dog (forward and backward). The precise shape of the cam dictates the stitch length and type.

- The Needle Bar: Driven by the cam system, the needle bar holds the needle and moves it up and down through the fabric. The timing of the needle bar’s movement is critical for accurate stitch formation.

- The Feed Dog: Another crucial component, the feed dog is a toothed metal bar that moves the fabric forward after each stitch. Its movement is also controlled by the cam system, ensuring consistent fabric advancement.

- The Bobbin and Shuttle: The bobbin holds the lower thread, and the shuttle carries it around the needle loop to create the lockstitch. Different machines employed various shuttle designs – rotating shuttles (Singer) and vibrating shuttles (Jones) being the most common.

- The Gear Train: A series of interconnected gears, carefully chosen for their gear ratios, transmit power from the main shaft to the cam system, needle bar, and feed dog. The gear ratios determine the speed and efficiency of each mechanism. Spur gears, bevel gears, and worm gears were all commonly used, each with its specific advantages.

The precision with which these gears were manufactured and assembled was paramount. Early machines relied on skilled machinists and hand-fitting techniques. As manufacturing technology advanced, more precise machining processes, like gear hobbing and milling, were employed, resulting in more consistent and reliable machines.

Incremental Innovations: Improving Efficiency and Functionality

The story of the vintage sewing machine isn’t one of a single breakthrough invention, but rather a series of incremental improvements and innovations. Here are some key developments:

- The Treadle Drive (1850s): Replacing the hand crank with a foot-operated treadle freed up both hands for fabric manipulation, significantly increasing sewing speed and efficiency.

- Improved Needle Systems: Early needles were often prone to breaking or bending. Developments in needle metallurgy and design led to more durable and reliable needles, capable of handling a wider range of fabrics.

- Automatic Bobbin Winders: Winding a bobbin by hand was a tedious task. Automatic bobbin winders simplified this process, saving time and effort.

- Vibrating Shuttle (Jones Family): The vibrating shuttle, introduced by the Jones family, offered a quieter and smoother sewing experience compared to the rotating shuttle.

- Differential Feed (Late 19th/Early 20th Century): This innovation allowed for simultaneous feeding of different layers of fabric, preventing stretching or puckering, particularly useful for sewing knit fabrics.

- Electric Motors (Early 20th Century): The introduction of electric motors powered by the burgeoning electrical grid revolutionized sewing, providing consistent power and eliminating the need for manual operation. These early motors were often belt-driven, connecting to the flywheel via a belt and pulley system.

- Attachments and Accessories: A vast array of attachments – rufflers, gatherers, binders, and more – expanded the capabilities of the sewing machine, allowing for a wider range of decorative and functional sewing techniques.

These innovations weren’t isolated events. They often built upon each other, creating a synergistic effect that continuously improved the performance and versatility of sewing machines.

Materials and Manufacturing: A Reflection of the Times

The materials used in the construction of vintage sewing machines reflect the technological capabilities and material availability of the time. Cast iron was the dominant material for the frame and major components, providing strength and rigidity. Steel was used for gears, shafts, and needles, offering durability and precision. Brass and bronze were employed for bearings and smaller parts, providing low friction and corrosion resistance. Wood, particularly hardwoods like walnut and oak, was used for the cabinet bases and decorative elements.

Manufacturing techniques evolved alongside the machines themselves. Early machines were largely handcrafted, with skilled machinists meticulously fitting each component. As mass production techniques developed, more automated processes were introduced, like casting, machining, and stamping. However, even in mass-produced machines, a degree of hand-fitting and quality control was maintained to ensure reliability. The quality of the materials and manufacturing processes varied between manufacturers and price points, with higher-end machines typically employing more robust materials and tighter tolerances.

The Cultural Impact: Democratizing Fashion

The widespread adoption of the sewing machine had a profound impact on society, particularly on the fashion industry and the role of women. Before the sewing machine, clothing was expensive and largely inaccessible to the working class. With the ability to produce clothing at home, families could save money and create garments tailored to their needs and tastes. This democratized fashion, allowing individuals to express their personal style and participate in the evolving trends of the time.

The sewing machine also empowered women. It provided a means for economic independence, allowing them to earn income by sewing for others or starting their own dressmaking businesses. It also fostered creativity and skill development, transforming sewing from a chore into a fulfilling hobby and art form. The rise of home sewing also fueled the growth of the pattern industry, with companies like Butterick and McCall’s providing readily available designs for fashionable garments.

The Legacy Continues: Studying the Past to Understand the Present

Vintage sewing machines aren’t just relics of the past; they offer valuable insights into the history of engineering, manufacturing, and social change. Studying their mechanisms reveals the ingenuity and problem-solving skills of the inventors and machinists who created them. Analyzing their materials and manufacturing processes provides a glimpse into the technological capabilities of the era. And understanding their cultural impact illuminates the profound ways in which technology can shape society.

Today, many vintage sewing machines are still in use, testament to their durability and quality. They are cherished by collectors, quilters, and sewists who appreciate their craftsmanship and unique character. Furthermore, the principles behind their design continue to influence modern sewing machine technology. While modern machines incorporate electronic controls and advanced features, the fundamental mechanics – the gears, cams, and needle systems – remain rooted in the innovations of the past.

The story of the vintage sewing machine is a compelling example of how scientific principles, engineering innovation, and cultural forces can converge to transform the way we live and express ourselves. It’s a story worth preserving and celebrating.

Interested in the fascinating intersection of mechanics and design in other historical objects? Explore the science behind vintage board game packaging, historical candle snuffers, historical recipe measurements, historical toy soldiers, or even antique sundials.

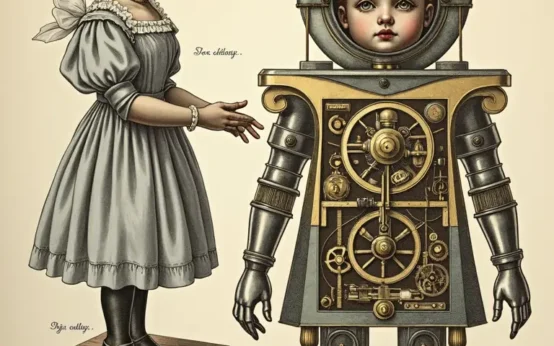

The Curious Anatomy of Antique Automata: Gears, Glamour, and Lost Ingenuity

The Curious Anatomy of Antique Automata: Gears, Glamour, and Lost Ingenuity